Silkscreen printing

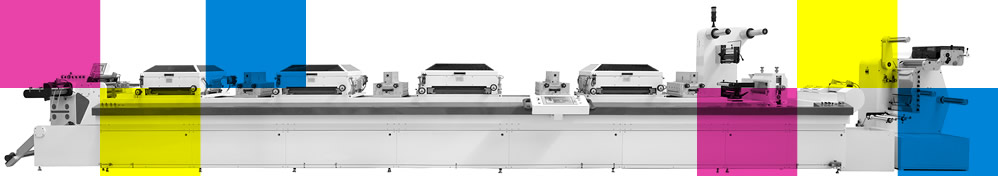

In-line screen printing and finishing. Mida SK series.

Servo-motorised screen printing unit

Basic configuration

Flat screen printing and rotary-die cutting on a single bench.

Other finishing options:

- FLAT BED: Hot-foil stamping and embossing.

- ROTARY: Flood or spot varnish, lamination with or without adhesive.

Flat silkscreen and rotary die cutting on a single bench

Silkscreen station

- Squeegee and wiper blade assembly running on rails to make sure the pressure on the screen is uniform in all printing widths.

- Speeds and pressures. Being the squeegee and wiper servomotor driven,speed and pressure are set from the touch panel.

- Separate speeds of squeegee for printing and of wiper for ink filling.

- Swivelling unit, pneumatic lifted, allows the cleaning of the screen without loss of register.

- Settings of squeegee and wiper, pressure and speed, from the touch panel without stopping printing.

Plataforms

- Intermittent: Only flat modules.

- Semi-rotary: Combination of flat and rotary modules on a single bench the web runs straight without intermediate loops.

Minimum web wastage during set-up

Features of Mida silkscreen printing unit

Benefits of SK series

- Flat silkscreen printing: Cheap, recyclable screens. Low-cost screen processing equipment. Many local suppliers

- Finishing tooling that is cheap and adapts to order size.

- Rotary die聽cutting in-line.

Technical data

| 聽 | SK |

| SILKSCREEN PRINTING | 聽 |

| Web width | 350 mm. |

| Print width | 330 mm. |

| Repeat length | 330 mm. |

| FINISHING | 聽 |

| Semi-rotary die cutting | 325 mm x 330 mm. |

| Flat bed embossing | 280 mm x 343 mm. |

| Flat bed hot foil stamping | 280 mm x 343 mm. |

| REWIND | 聽 |

| MONOBLOCK | 聽1×800 |

| BOB 350 IN LINE | 聽1×800 + 1×400 |

For more technical details see brochure of the SK series.